|

|

|

|

|

The Log Flume may have been one of the most complex of the construction

projects from the initial build-out of the park in 1974. Like the rest

of the park, great care was taken to preserve as many trees as possible

during construction, maintaining the idea of the Enchanted Forest where

attractions were well hidden by the trees. Since the peninsula where

the Log Flume was located was not slated for additional development in

the first phase of construction, clearing just enough land for the ride

itself and the construction vehicles required careful planning and

coordination. The peninsula and the surrounding land was quite swampy

which added an additional challenge to the project.

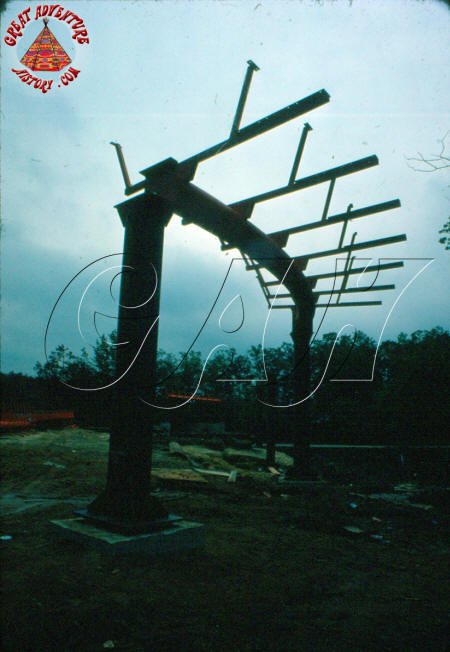

The first

phase of the project involved pouring the concrete footers for the steel

supports. Once the concrete cured, the steel columns were placed along

the ride path. |

|

|

|

|

|

|

|

|

|

|

With the supports in place, the steel spine of the trough was placed

section by section. The spine of the Arrow Dynamics designed

trough was designed very much like the steel roller coasters built by

the company (like the neighboring Runaway Mine Train) with a central

steel tube with welded brackets for the steel supports. |

|

|

|

|

|

|

|

|

The trough supports were assembled on site with the trough frames being

attached to the spine on the ground prior to the track sections being

lifted into place.

While all the work was happening on the raised

track sections, other construction teams were hard at work on the ground

level sections of the trough where the final splash-down took place.

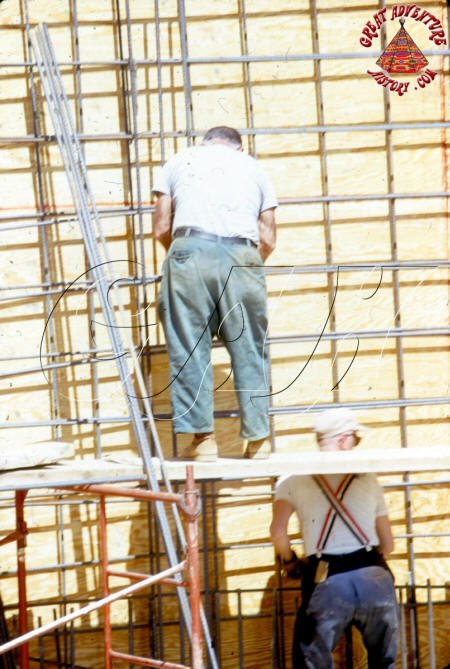

Work also progresed on the concrete retention basin and station structures. The lower walls of the station were poured concrete and required

construction of plywood forms and steel rebar frames. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The base of the station required a foundation which would support the

encircling trough as well as the loading turntable. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once the foundation was set, it was backfilled with sand as the concrete

walls were poured layer by layer to the finished height. A concrete

floor was poured and additional concrete columns were added to support

the turntable and trough. The area below the turntable was designed to

serve as sort of a basement for maintenance of the motor that drives the

rotation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

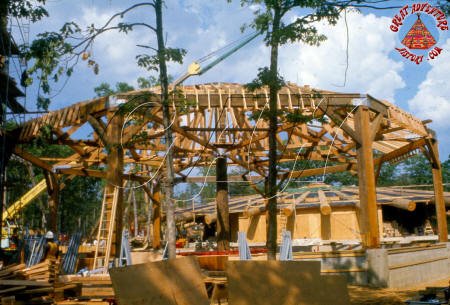

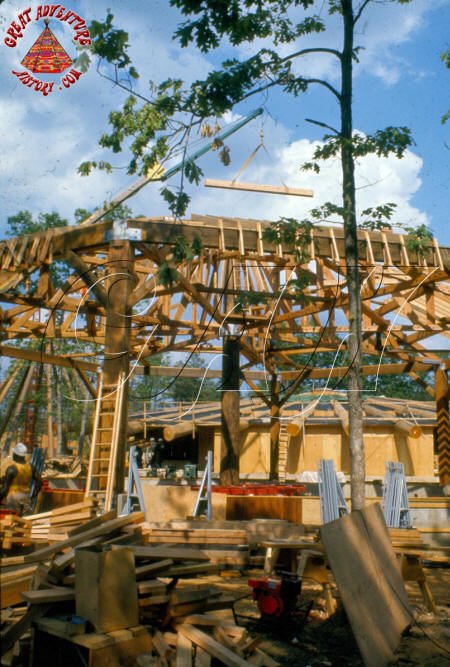

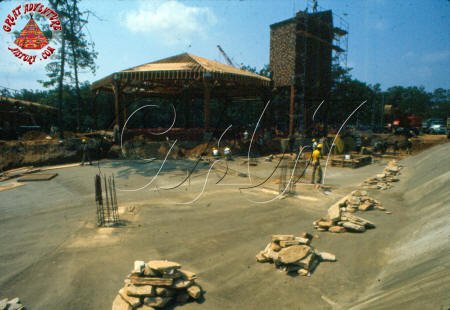

Once the concrete lower portions of the station were completed, the

carpenters came in and began construction of the wooden structure. The

eight corner columns around the edge of the octagonal building along

with the round central column went up first, then scaffolding was

erected to complete the outside framework and begin construction of the

roof structure.

The roof was made of piece built trusses to

provide the strength to stand up to heavy winter snow while creating an

open and airy station for the hot summer days. Below, the steel

framework for the turntable took shape. This would be clad with marine

plywood to form the circular platform. |

|

|

|

|

|

|

|

|

|

|

|

|

|

As opening day drew ever closer, the station began to take its final

shape. The tradesmen were working long hours to get things finished for

the July 1st opening date, with teams simultaneously building the

station, track structure and the masonry. The tower and waterwheel were

built at the same time as the rest of the station, creating the entrance

and exit stairways from the queue. The final touch of the carpenters'

work was adding the wooden shingles on the roof and covering the walls

of the tower and pump buildings.

The mechanical parts of the ride

like the pumps and plumbing along with the lift belts were installed

towards the end of the process. One of the last parts to be installed

was the ride's access stairways, catwalks and railings along the length

of the ride track. |

|

|

|

|

|

|

|

|

|

|

|

|

With all the concrete retention basins in place, the decorative stacked

stone for the walls and columns was placed by the masons, giving the

ride a more rustic look and creating visual interest for what could have

been a simple concrete pool. |

|

|

|

|

|

|

|

|

|

|

|

![]()