|

|

|

|

|

|

The most expensive and one of the most elaborate structures built at

Great Adventure in 1974 as part of the initial construction was Best of

the West. The building was designed as a true timber frame structure

utilizing massive logs. The enormous logs required were harvested and

trucked down from Canada's Yukon Territory. The transcontinental trip

must have been long and somewhat dangerous but speaks of the authentic

details that Warner LeRoy was striving for in the park. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

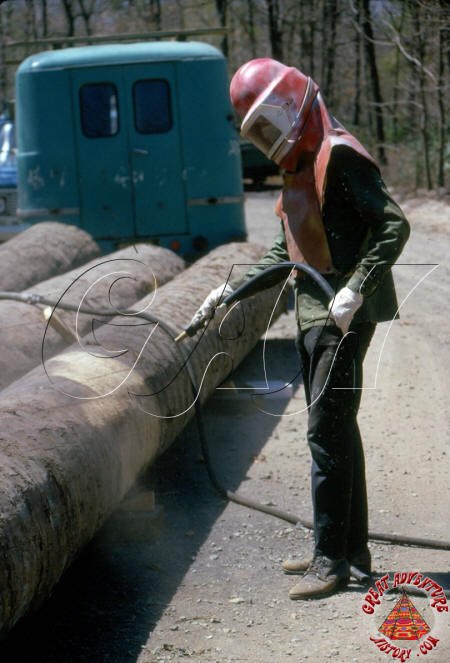

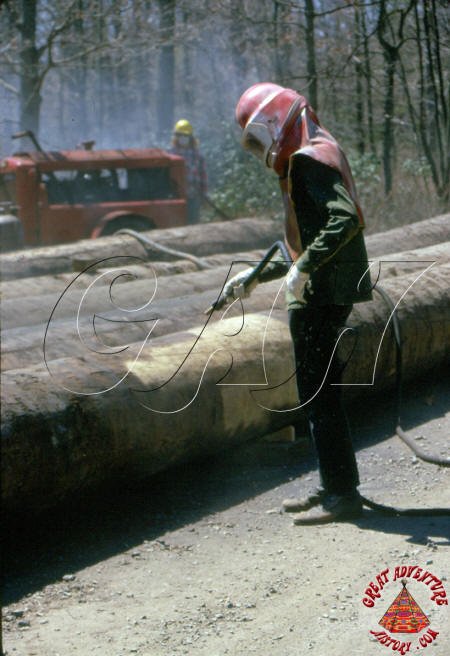

Upon arrival the logs were prepared for construction. Part of the

process was sandblasting the exteriors of the logs to remove any

remaining bark as well as the accumulation of road dirty from the nearly

4000 mile journey from the Yukon.

Once the logs had been

prepared, the logs were marked out for construction with holes,

notches and cuts having to be made on the ground and very precisely so

when they were hoisted into place they would fit together like a giant

set of Lincoln Logs. |

|

|

|

|

|

|

|

|

|

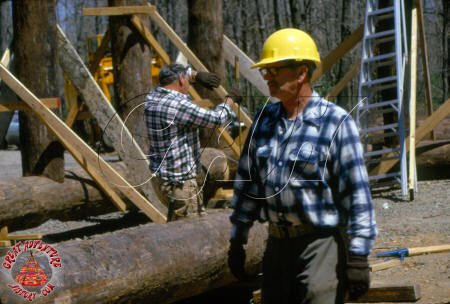

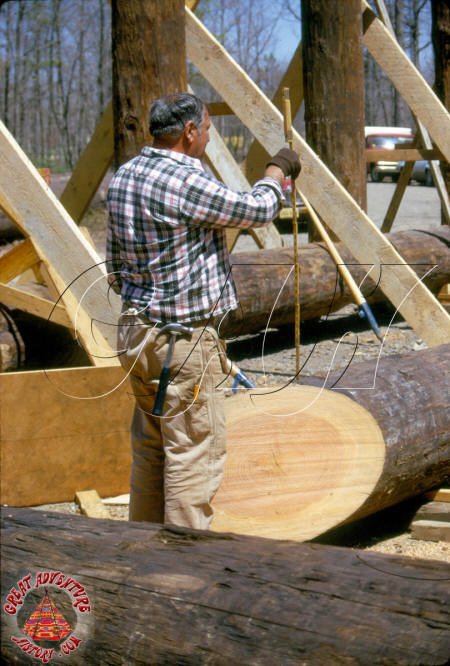

Each piece was cut, notched and labeled for assembly. One of the most

amazing things to note about the process is just how much of the work

was done by hand and how much skill it took on the part of the

construction crew to carefully shape and pre-cut the logs in order to

make them fit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A temporary shed was in place for the construction workers to take

shelter from the elements to keep on schedule. Temporary rails were laid

for moving the heavy logs out of the shelter and into place for

construction. With the very tight timeline for construction, all of the

cutting and assembly had to be done in just a couple of months. The log

framework itself appears to have been completed in the course of about

three months. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

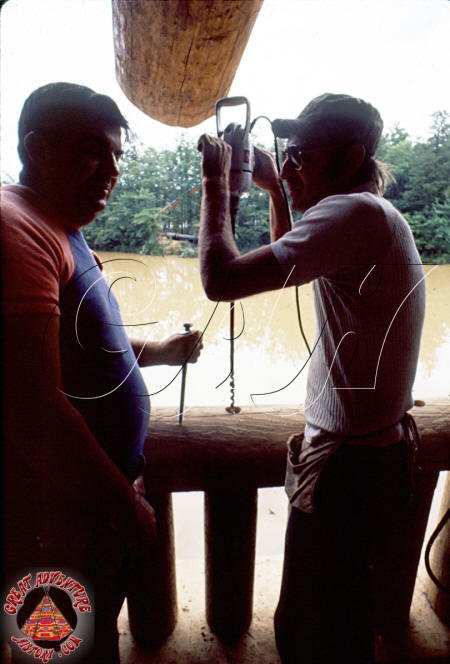

A wide range of tools and skills were utilized for the construction

including hand saws, chainsaws, axes, hatchets and drills. The hand-made

quality of the building made construction time consuming but added to the

rustic authenticity of the building. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

While all the logs were being cut and shaped, other crews were hard at

work on the foundation of the building and the "basement" level. The

foundation of the building went right up to the edge of the lake and an

additional boardwalk was built over the lake which would create the

pathway around the back of the building. The "basement" would serve as

the location for the air conditioning units for both Best of the West as

well as the adjoining Super Teepee. This was also where the compressors

for the building's walk in refrigerator and freezer were housed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once the foundation was completed, the

first of the massive log walls began to take shape. The upright logs

went vertical and were capped by the long sills that would support the roof

beams. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On the back side of the building where the kitchen was located a steel

framework was built for the walk-in refrigerator and freezer units.

Simultaneously the restaurant's concrete floor was being formed with

rebar on top of the sand fill. |

|

|

|

|

|

|

|

|

|

With the outer walls framed, the workers assembled the central support

structure and began stringing the roof logs. A scaffold was setup in

the middle allowing the crew easy access as each beam was hoisted into

position with a crane. Once all the logs were in place, the roof was

sheathed and covered with rustic roofing materials. The center section

of the building was outfitted with a skylight which allowed the natural

light to fill the huge space. |

|

|

|

|

|

|

|

|

|

|

With all the main building construction completed, the work crews turned

their attention to the finish details like the log railings. Despite the

best efforts of the construction crews, Best of the West along with the

rest of the Rootin' Tootin' Rip Roarin' section wasn't quite ready for

the July 1st opening day, but opened just three days later on July 4th. |

|

|

|

|

|

|

|

|

|

|

|

|

|

![]()